high quality dirty water drainage pump factory

Latest articles

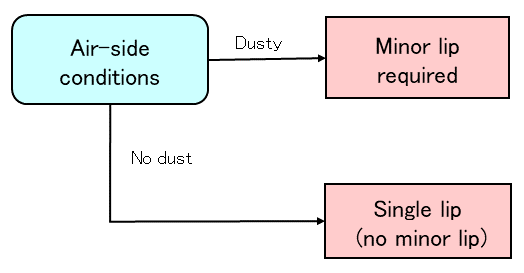

What is the best seal arrangement for the application?

high quality dirty water drainage pump factory...

high quality dirty water drainage pump factory 【high quality dirty water drainage pump factory】

Read MoreFirstly, analysing your duty helps us to determine whether you are using the type and size of pump best suited to your needs. Cavitation can occur due to surges; a very effective way to solve this problem is to install a choke on the pump head to increase the pressure on the casing, which then absorbs the surge, or to add a choke to the output to reduce the surge.

high quality dirty water drainage pump factory...

high quality dirty water drainage pump factory 【high quality dirty water drainage pump factory】

Read More- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

high quality dirty water drainage pump factory...

high quality dirty water drainage pump factory 【high quality dirty water drainage pump factory】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

high quality dirty water drainage pump factory...

high quality dirty water drainage pump factory 【high quality dirty water drainage pump factory】

Read MoreMagnetite mixing

high quality dirty water drainage pump factory...

high quality dirty water drainage pump factory 【high quality dirty water drainage pump factory】

Read MoreConsider the following.

high quality dirty water drainage pump factory...

high quality dirty water drainage pump factory 【high quality dirty water drainage pump factory】

Read More- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

high quality dirty water drainage pump factory...

high quality dirty water drainage pump factory 【high quality dirty water drainage pump factory】

Read MoreWill solids size pass through the pump?

high quality dirty water drainage pump factory...

high quality dirty water drainage pump factory 【high quality dirty water drainage pump factory】

Read MoreWhat is the best seal arrangement for the application?

high quality dirty water drainage pump factory...

high quality dirty water drainage pump factory 【high quality dirty water drainage pump factory】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

high quality dirty water drainage pump factory...

high quality dirty water drainage pump factory 【high quality dirty water drainage pump factory】

Read More

Popular articles

- Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

- method and level of design reach international advanced level. The company has the first-class pump performance

- How to choose a slurry pump?

- Many types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

- Sump drainage or washdown

- Larger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

Latest articles

-

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

-

Selecting a dredge pump

-

>Slurry Pump VS Mud Pump

-

When flushing is required, the >slurry pump supplier recommends the API Option 32 sealed pipe arrangement as it is more suitable for services containing solids or contaminants that could damage the seal faces if recirculated in the flushing medium.

-

Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

-

If you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

Links

- An auto gasket, a seemingly insignificant component, plays an essential role in the overall functionality and performance of a vehicle. A gasket is a thin, usually ring-shaped seal that is designed to fill the space between two or more mating surfaces, preventing leakage from or into the joined components. In automotive engineering, gaskets are vital for maintaining the integrity of various systems, including the engine, transmission, and cooling system.

Table 1: The order of priority for selecting oil seals

Outer case

- We highly recommend to use special tools when installing oil seals without a plastic sleeve. You can find the advice around the right tool from the manufacturer.

- Temperature range between -15 degrees Celsius to 185 degrees Celsius

Most standard oil seals have to comply with the DIN 3760 and ISO 6194 standards. Different standard types of oil seals are available that comply with these requirements.

Synthetic Rubber Oil Seals - Styrene Butadiene Rubber oil seals, or just SBR oil seals, offer strong resistance to abrasions and lesions, making them an ideal seal for fast-moving machinery. With the ability to withstand extreme temperatures with its heat-aging qualities, they can be used in outdoor components. They are also seen as more cost-effective oil seals than natural rubber.

Our standard and custom rubber oil seals can match the increasingly demanding applications of any industry.

- Electrical motors

- In conclusion, auto parts oil seals play a vital role in the smooth operation and longevity of vehicles. These seals prevent the leakage of fluids in critical areas such as the engine, transmission, wheel bearings, and differentials. Regular maintenance and inspection of oil seals are essential for ensuring that they are functioning correctly and preventing any leaks. By understanding the importance of oil seals in auto parts, vehicle owners can prolong the life of their vehicles and avoid costly repairs.

It also reduces the likelihood of fouling, thereby prolonging the plug's lifespan It also reduces the likelihood of fouling, thereby prolonging the plug's lifespan

It also reduces the likelihood of fouling, thereby prolonging the plug's lifespan It also reduces the likelihood of fouling, thereby prolonging the plug's lifespan

For instance, silicone rubber gaskets are resistant to extreme temperatures, making them ideal for use in automotive engines, while neoprene gaskets are known for their durability and resistance to oil and chemicals, thus finding extensive use in industrial settings For instance, silicone rubber gaskets are resistant to extreme temperatures, making them ideal for use in automotive engines, while neoprene gaskets are known for their durability and resistance to oil and chemicals, thus finding extensive use in industrial settings

For instance, silicone rubber gaskets are resistant to extreme temperatures, making them ideal for use in automotive engines, while neoprene gaskets are known for their durability and resistance to oil and chemicals, thus finding extensive use in industrial settings For instance, silicone rubber gaskets are resistant to extreme temperatures, making them ideal for use in automotive engines, while neoprene gaskets are known for their durability and resistance to oil and chemicals, thus finding extensive use in industrial settings